A case study in complex energy system optimisation

Bosco Printed Circuits is the largest maker of Printed Circuit Boards (PCB’s) in South Africa. The production line at Bosco needs a lot of energy. The direct and indirect consequences of losing energy supply to the line are substantial.

Johannesburg, where Bosco are based, has significant issues with energy supply – both in terms of reliability and also (as a consequence) in terms of energy cost.

Like most businesses, Bosco already had an extensive solar array installation, which certainly helps with the economics of energy supply. The solar array is not sufficiently effective, is isolation, to address the complex challenges for the business in terms of supply cost and supply security.

Energy supply to Bosco from the grid utility is time-of-day based. The energy supply cost is very high during distinct morning and evening peak periods, to discourage energy use in those times. These peak time bands are periods of high energy requirement for Bosco. The are the times when the potential for grid failure is greatest and are also the periods when the consequences of grid failure for Bosco are the most severe.

Of course, these times (early morning, late afternoon) are also exactly the periods when the solar arrays can’t help, as they are outside of the solar peak generation periods.

Grid outages are expensive for Bosco. Not only do they result in lost productivity, but they also have further economic consequences in terms of partially produced PCB’s having to be scrapped when the production machines are halted without warning.

The Challenge

Bosco had a variety of business aims and objectives across their daily operating cycle that their energy system had to address:

- To ride over transient periods of grid loss seamlessly using battery energy

- To support the operation of the production line for an extended period (hours, not merely minutes) in the face of longer periods of grid outage, so that the company can keep working, using battery energy augmented with any available solar energy, for as long as possible.

- In cases of a very extended grid outage (several hours), to allow the production line to be closed down with plenty of warning (at least an hour) from the point at which the shutdown decision is made.

- To time-shift energy obtained from the low cost overnight off-peak period into the morning peak period (0600-0800), prioritising battery energy usage at this time in order to minimise the use of very expensive grid energy.

- To also minimise afternoon peak-period grid usage by again prioritising the use of battery energy in this second daily period

- To use the residual battery energy, harvested from overnight off-peak charging and from any excess of daytime solar power, to supply the background energy needs of the building into the evening.

- To recharge the battery array again using off-peak power from midnight to 6am ready to commence the next daily cycle.

This need set required a battery energy system capable of consistent hard work and capable of daily 100% energy discharge, working in a hot environment, and without loss of output capacity over time.

The Solution

The solution uses 14 x Redflow ZBM2 batteries (140kWh) interfaced to a large array of Victron Energy inverter/chargers and a large solar array.

The system orchestrates this complex daily cycle of energy optimisation using the Victron CCGX and the Redflow BMS, to achieve the aims and objectives noted above.

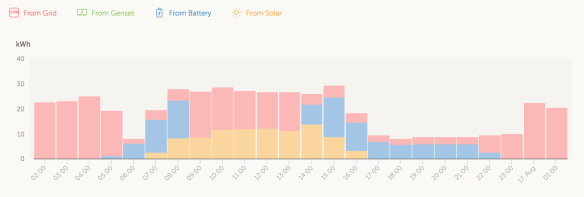

Here’s a typical day in the life of this system, in terms of the sources of energy to run the plant:

Bosco Printed Circuits Energy Consumption

You can see the periods where the battery system energy (blue) is prioritised in order to minimise the use of grid energy during peak times. You can see the battery being fully utilised to supply energy during the afternoon and evening as the solar consumption falls away, and you can see the system recharging using off-peak energy again from midnight, ready for the following day.

You can use this Bosco Printed Circuits VRM Portal Link to see the live system running.

Bosco ZBM storage array (12 batteries shown – a further 2 were added later)

You must be logged in to post a comment.